Ultrasonic Plastic Welding Machine Generator 15/20kHz 2000/3200Watt

- Description

- Inquiry

Description

Specification

An ultrasonic plastic welding machine generator is a device used in ultrasonic plastic welding processes. It generates high-frequency electrical signals that are converted into mechanical vibrations by a transducer. These vibrations are then used to join plastic parts together through a combination of pressure and heat generated at the welding interface. The generator provides the power necessary for the welding process to take place.

Product name | Ultrasonic Plastic Welding Machine Generator |

Installation dimensions | 360mm x 245mm x 95mm |

Net Weight | 5.6 KG |

Generator Display | 3.5-inch high resolution color LCD screen |

| Frequency | 20/15khz |

| Power | 2000/3200 watt |

| Automatic frequency tracking accuracy | 0.1Hz |

Power repetition consistency | ≥97% |

| Power Supply | AC190-AC240V 50Hz/60Hz |

Communication methods | 485 communication, support standard MODBUS RTU protocol |

| Dynamic response time of remote terminal | ≤10ms |

Welding Mode | Time, Energy, External Control, Spot Welding |

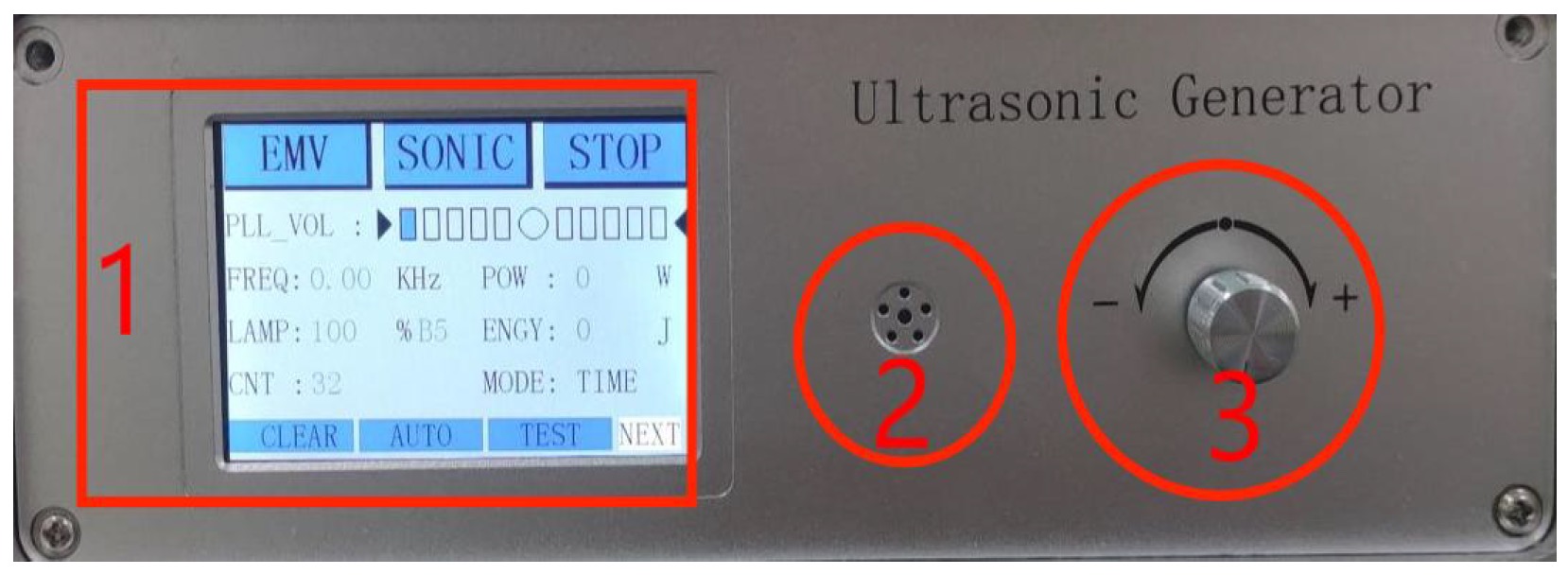

1.LCD color LCD display.

2. Horn of buzzer.

3. Multi-function knob can be rotated and pressed left and right.Rotate left and right to move the cursor, click the knob to confirm the current cursor selection, and double click the knob to exit the current cursor selection.

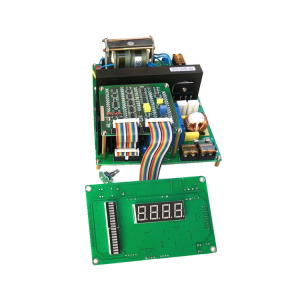

1. Power switch.

2.220V ac interface.

3. Cooling fan outlet, there should be no shielding within 15cm around the outlet to ensure the cooling effect.

4. 3 core aviation plug,

(1) pin start switch at one end (start switch is normally open).

(2) the foot is the public end, connected to the start switch and emergency stop switch at one end;The foot is connected to the end of the emergency stop switch (emergency stop switch is normally closed).

5. 2-core aviation plug:

(1) pin 485A,

(2) pin 485B.

6. 2 core aviation plug:

(1) pin connected to the negative pole of the transducer.

(2) pin connected to the positive pole of the transducer.

Ultrasonic Plastic Welding Machine Generator Advantages

- It has intelligent learning function to automatically match the transducer.

- Equipped with sound resistance feedback to increase welding stability.

- Adjustable lower frequency to adapt to a wider range.

- High-precision Hall sensor detection function, with a control accuracy of up to 0.5%.

- Complementary dual-phase full-bridge design for exceptionally strong bursting power.

- Non-linear power output for intelligent power delivery.

- Supports standard MODBUS protocol for RS-485 communication.

- All-aluminum alloy casing, color LCD display screen with exquisite image quality.

- Equipped with intelligent protection against over-temperature, over-current, and 11 categories of abnormal alarm systems to safeguard molds, ensuring safe use.

- Supports continuous load changes and heavy load power fluctuations.

- Supports point welding frequency of up to 240 times per minute for efficient and stable operation.

- Frequency is not prone to loss of synchronization, ensuring stable operation.

Please contact us sales@intopindustrial.com to get more information about our Ultrasonic Plastic Welding Machine Generator and get a quotation!