Ultrasonic Lace Sewing machine

- Description

- Inquiry

Description

Specification

The ultrasonic lace sewing machine is a specialized piece of equipment used in the textile and garment industry for various sewing and fabric joining applications. Unlike traditional sewing machines that use needles and thread, ultrasonic lace sewing machines use high-frequency ultrasonic vibrations to bond or weld synthetic fabrics together. These machines are particularly useful for non-woven fabrics, thermoplastic materials, and certain types of films and foils.

| Source power | 220V +/- 5V 50/60HZ 6A | ||

| Input power | 1500-2500W ( Adjustable) | ||

| Output frequency | 20kHz | ||

| Working speed | 0-20m/min | ||

| Roller size | Width 0-100mm, Diameter 50- 60mm | ||

| Working temperature | ≤ 25℃ | ||

| Packaging Dimension | 1200×600×1200mm | ||

| Gross Weight | 130KG | ||

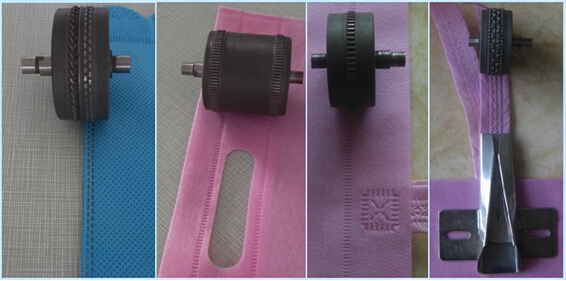

Basic components

1. New type PC intellectual ultrasonic generator.

2. 20kHz Ultrasonic transducer unit.

3. Bottom mould fixed suspension structure.

4. Single motor speed adjustment system.

5. Manual(or Pneumatic) roller lifting system.

6. Double-barreled framework and heavy support board.

Ultrasonic Lace Sewing machine Application

Ultrasonic lace sewing machines have a wide range of applications across various industries, primarily in situations where the bonding, cutting, or sealing of synthetic fabrics and materials is required. Some of the common applications of ultrasonic lace sewing machines include:

- Textile and Apparel Industry:

- Lace pattern cutting: The ultrasonic machines can create intricate lace patterns on garments, lingerie, and other textile products.

- Seam sealing: Ultrasonic sewing machines are used to seal seams on clothing, preventing fraying and enhancing durability.

- Quilting: They are employed in quilting operations for creating quilted patterns on fabrics.

- Medical and Hygiene Products:

- Disposable medical gowns and masks: Ultrasonic lace sewing machines are used to bond non-woven fabrics for the production of disposable medical garments and masks.

- Surgical drapes and covers: They help in creating sterile barriers in the medical field.

- Packaging Industry:

- Packaging materials: The ultrasonic embossing machines are used to create seals in various types of packaging materials, such as plastic bags and pouches.

- Filtration Industry:

- Air filters and liquid filters: Ultrasonic lace sewing machines are used to bond and seal filter media in filter manufacturing.

- Electronic Industry:

- Bonding and sealing electronic components: They can be used for sealing wires, cables, and insulating electronic components.

- Stationery and Packaging:

- Production of stationery items like folders, document holders, and packaging inserts.

- Customized and Branded Products:

- Ultrasonic lace sewing machines can be programmed to create customized lace patterns and designs, making them valuable for producing branded products with unique aesthetics.

- Filters and Filtration Materials:

- Manufacturing various types of filters, such as air filters, liquid filters, and oil filters.

Ultrasonic lace sewing machines offer advantages such as precision, speed, cleanliness, and the ability to work with a variety of synthetic materials. Their applications continue to expand as new technologies and techniques are developed to meet the evolving needs of industries that require fabric bonding, cutting, or sealing.

Please contact us sales@intopindustrial.com to get more information and a quotation now!