Ultrasonic Spraying Machine

- Description

- Inquiry

Description

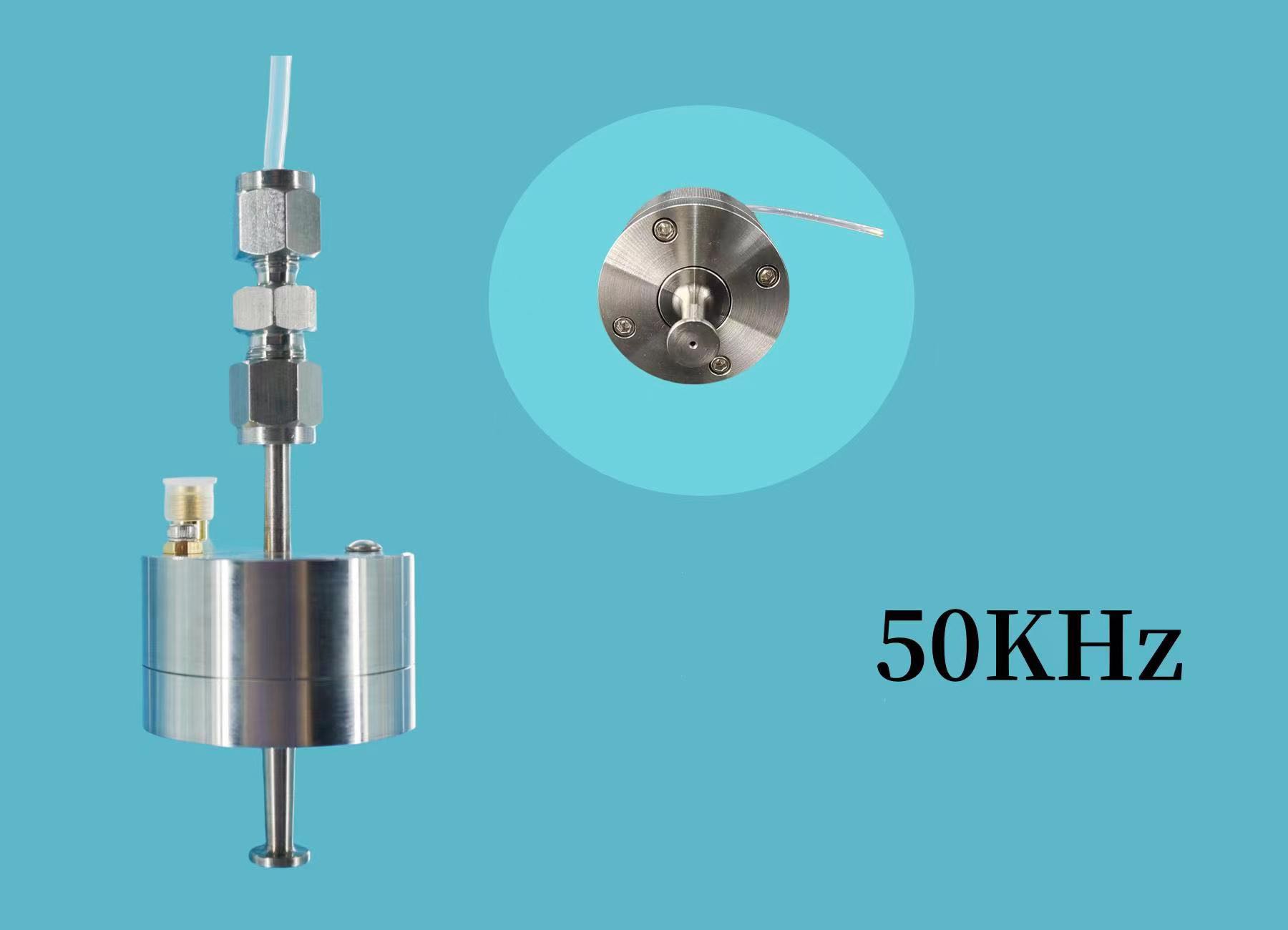

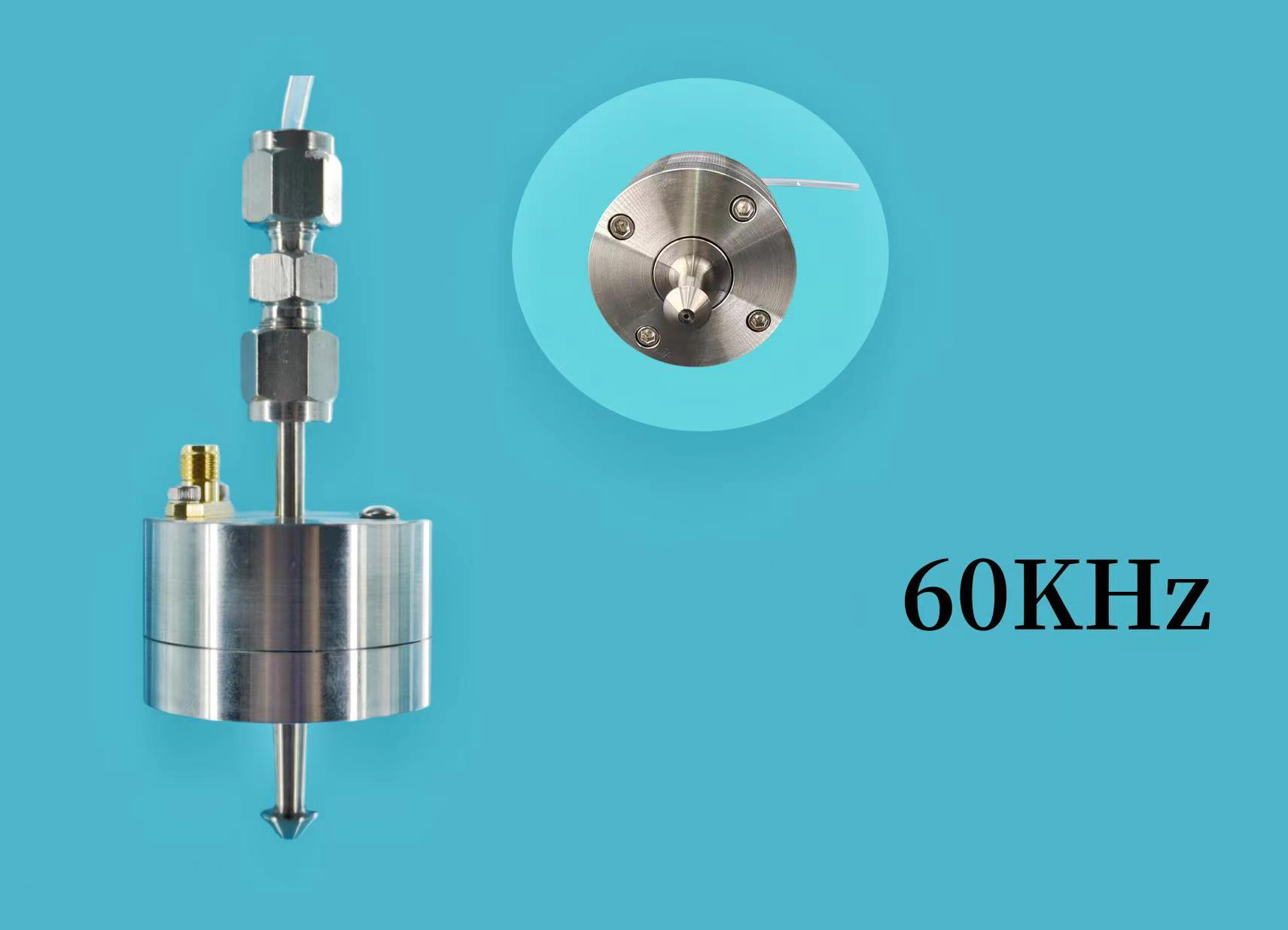

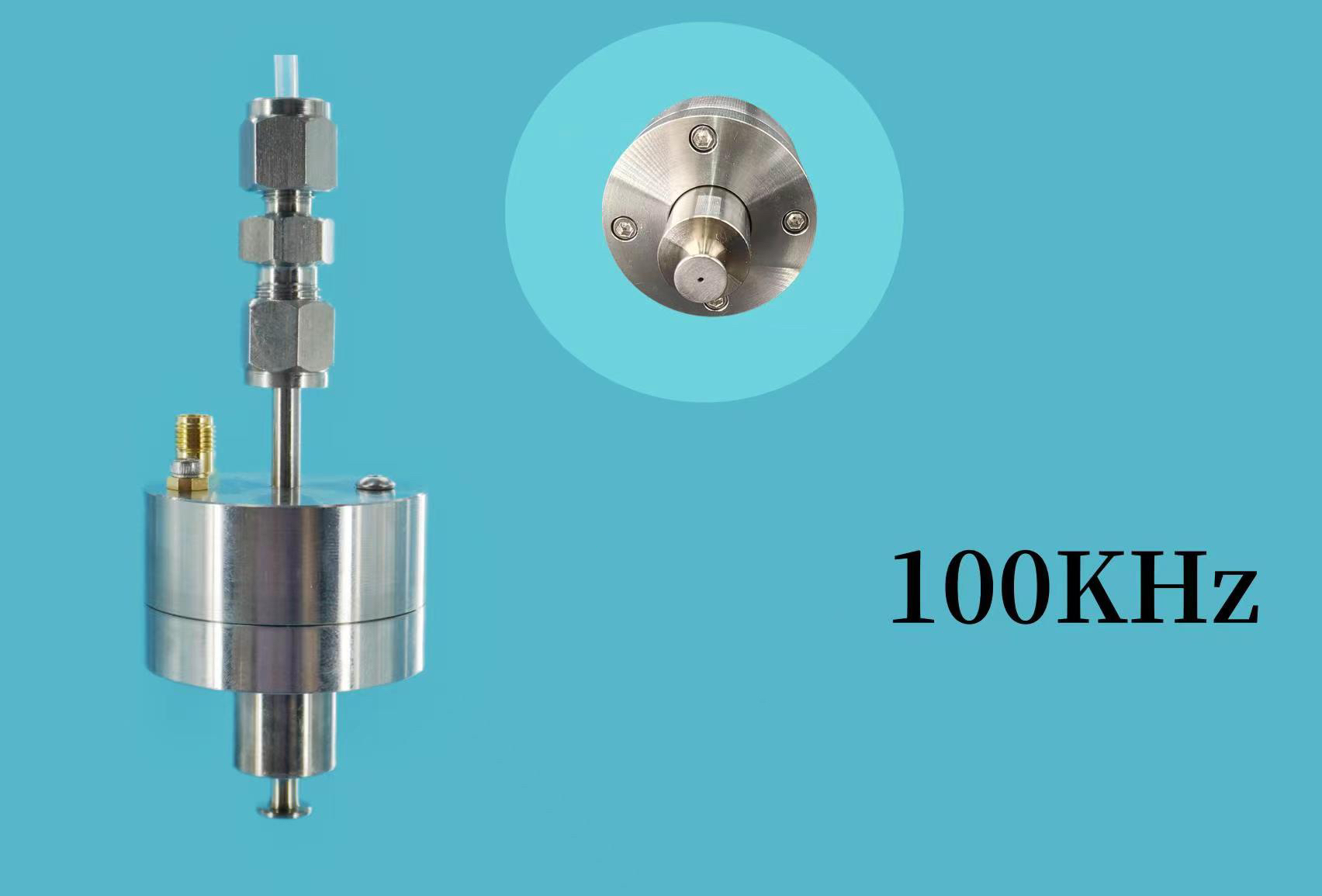

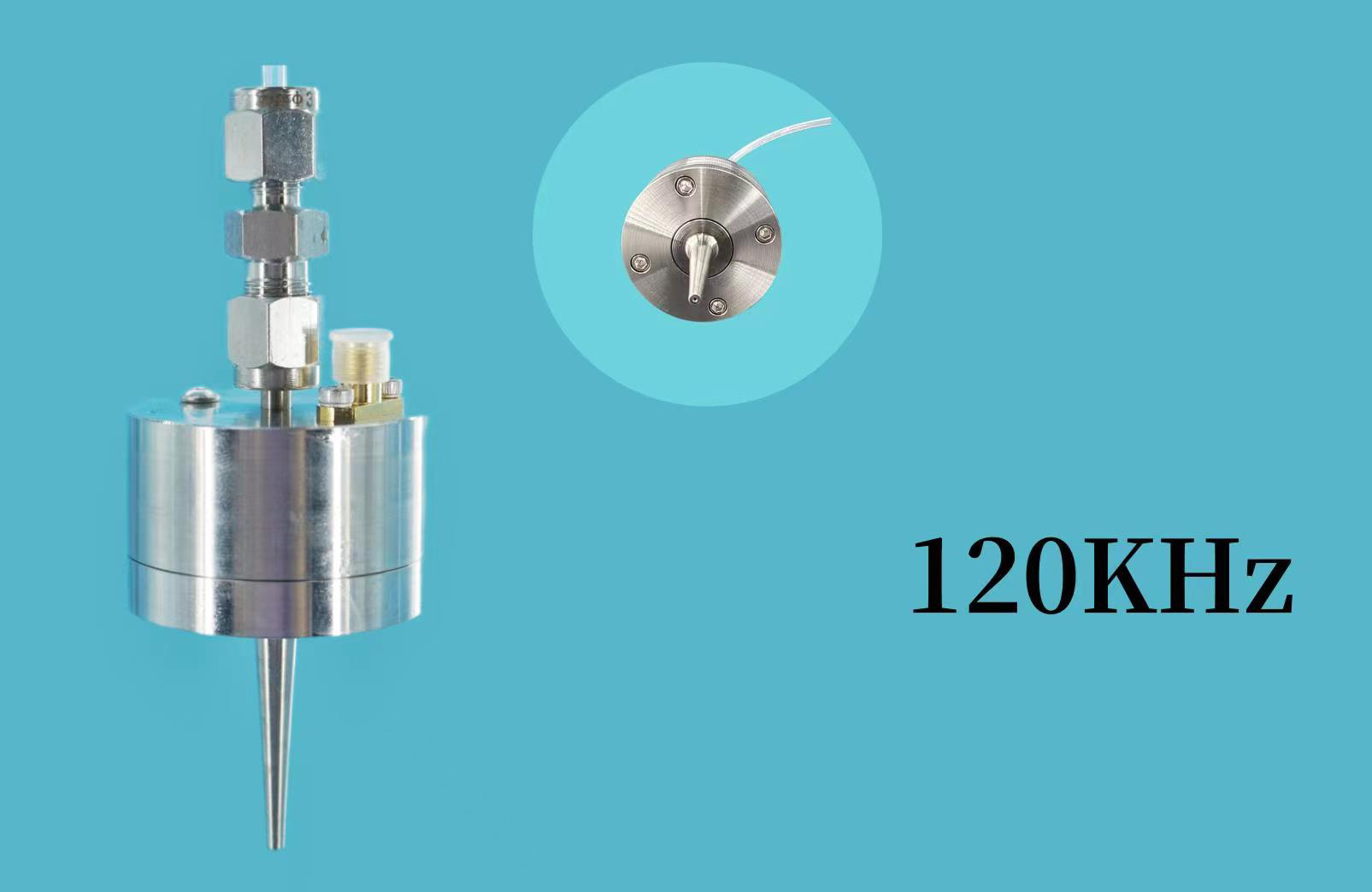

Ultrasonic Spraying Machine Specification

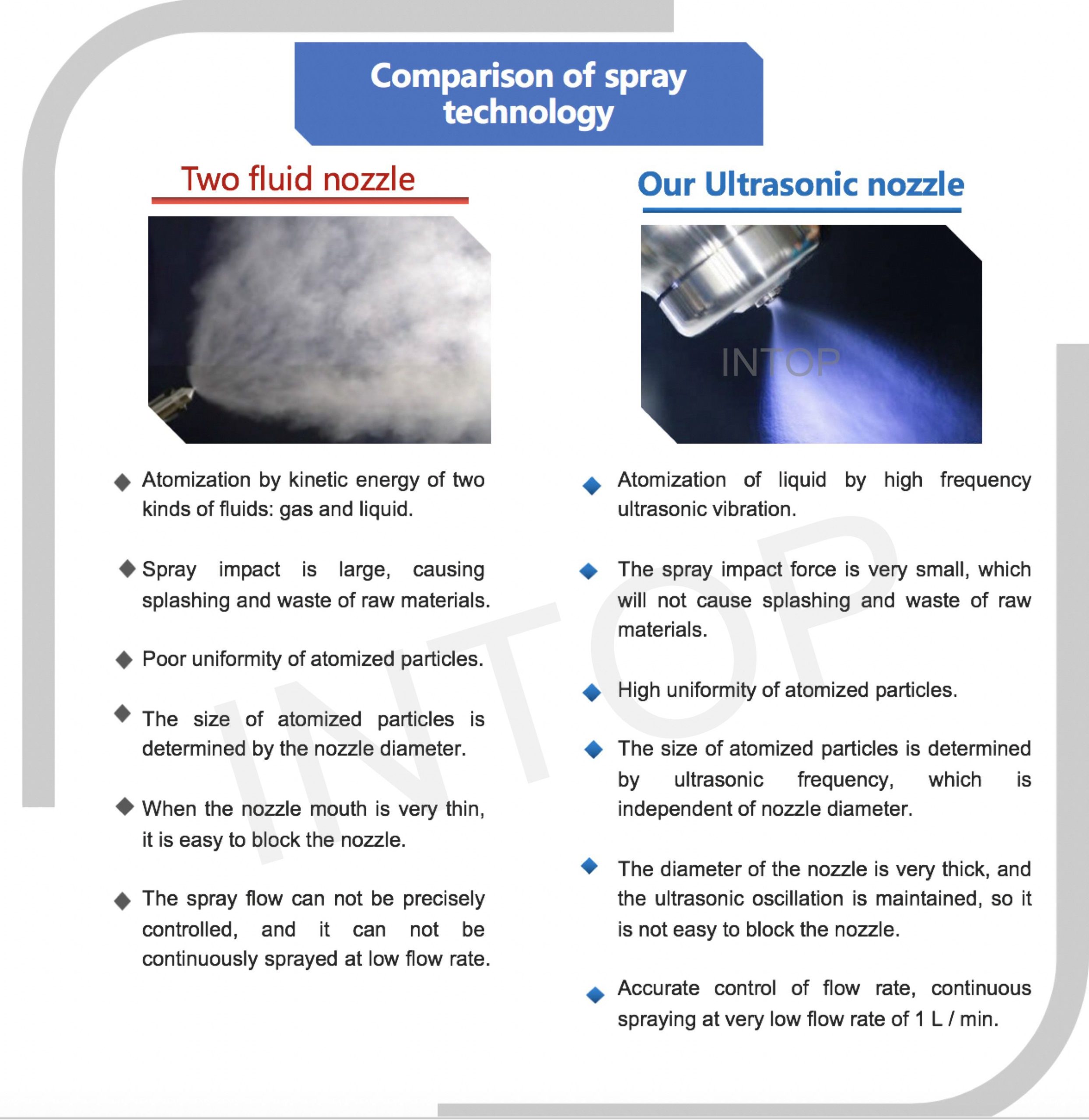

An ultrasonic spraying machine is a specialized piece of equipment that utilizes ultrasonic technology to atomize and disperse liquid substances into fine droplets or mist. This technology is commonly used in various industrial applications for precise and efficient coating, spraying, and atomizing of liquids.

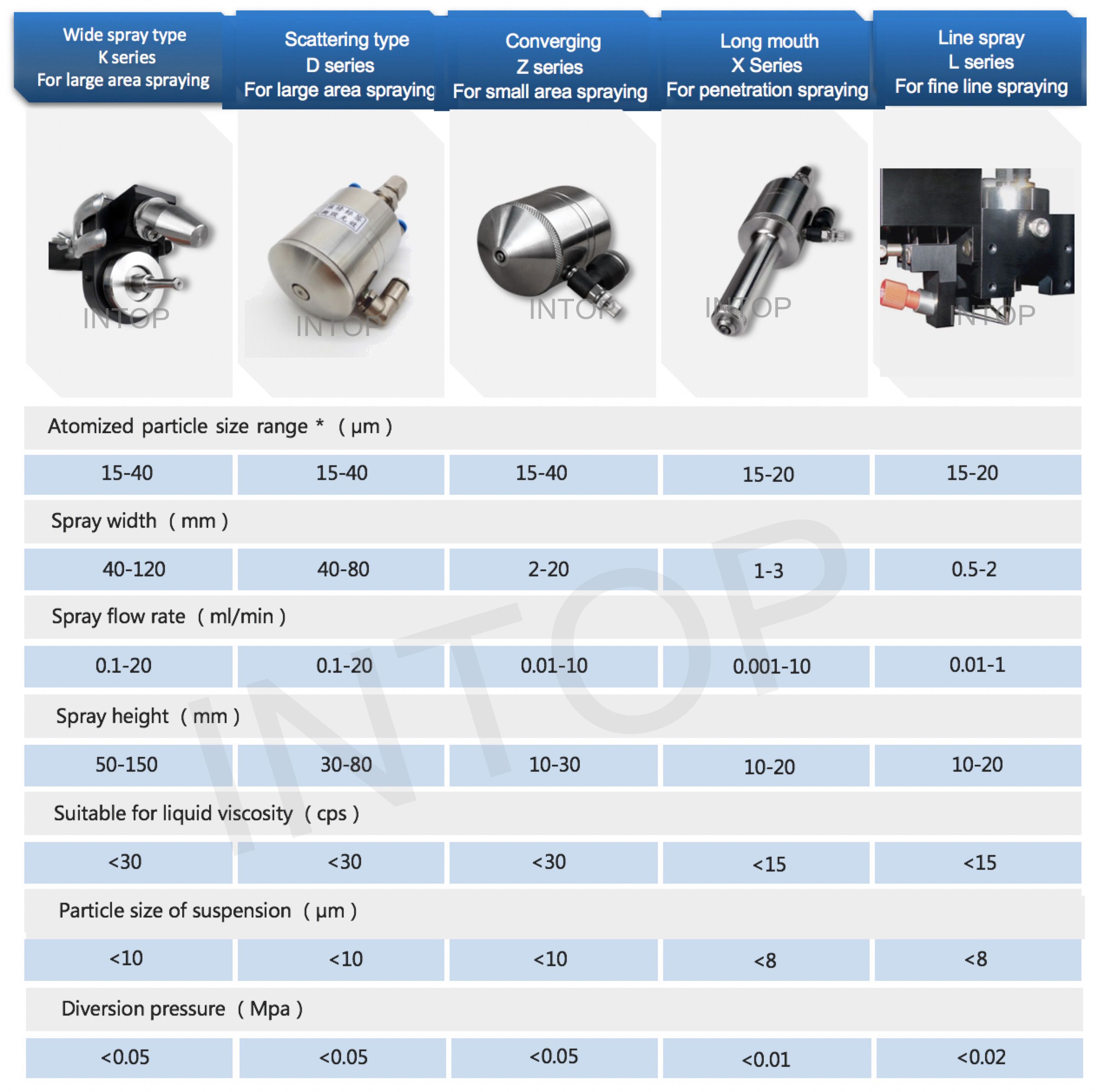

Through different frequency and air passage design, different atomizing particle size and wide spray width can be produced to meet different spraying requirements such as different area, thickness and finish. In addition, the unique design of the shape structure can also be adapted to high temperature, narrow space and other special environments, such as spray coating, spray drying, spray pyrolysis, etc.

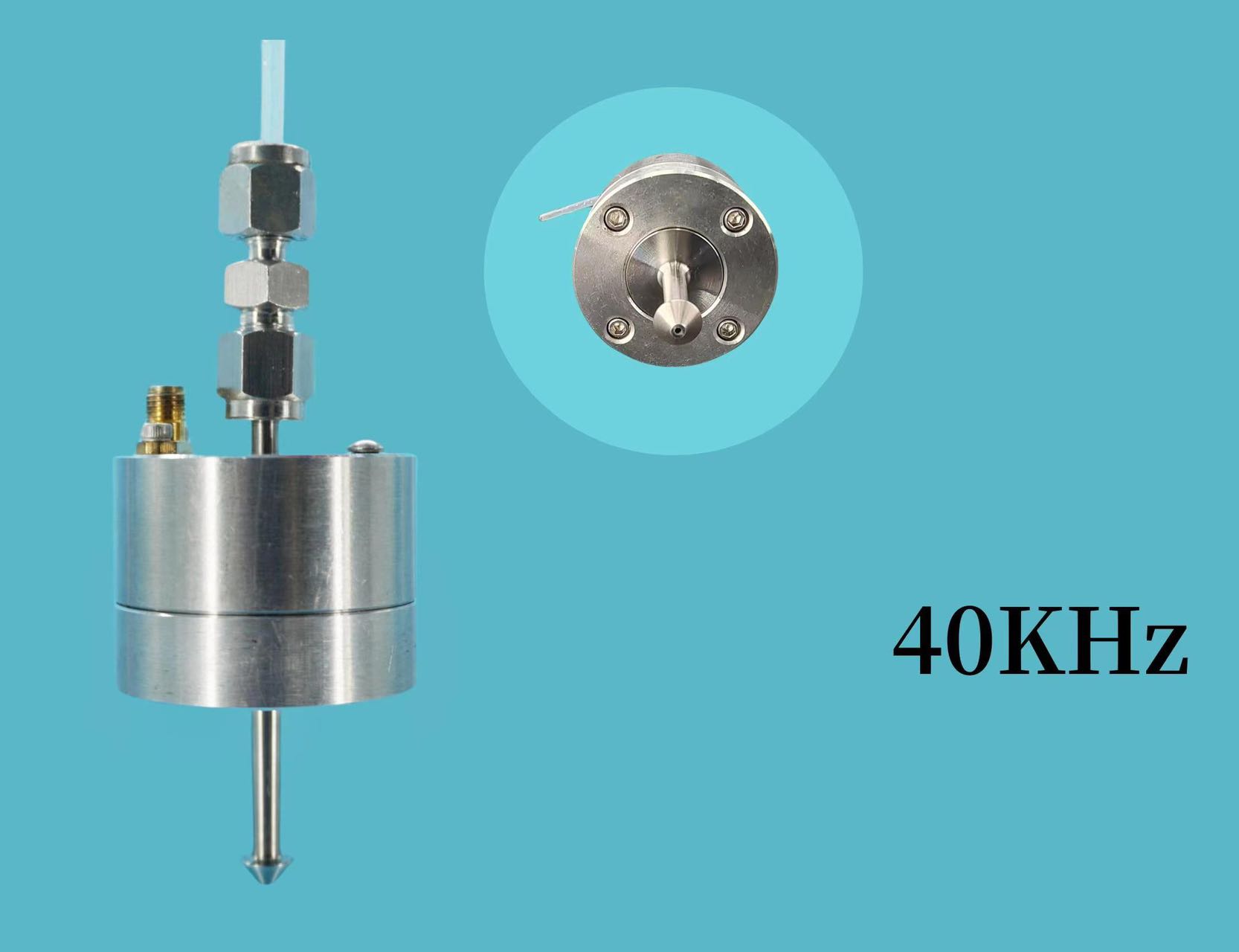

| Frequency (kHz) | Maximum flow rate (ml/s) | Median Droplet diameter (µ) |

| 25 | 3.3 | 55 |

| 35 | 6 | 49 |

| 48 | 2.9 | 25 |

| 60 | 1.2 | 25 |

| 120 | 0.35 | 15 |

Our Ultrasonic Spraying Machine advantages

1. High stability

The ultrasonic spraying machine is made of high-performance titanium alloy and stainless steel, with strong adaptability and corrosion resistance, no pressure, no noise, no nozzle wear and blockage, and high uniformity of atomized particles.